Test No. VNL05 Find residual deformations in a bar

axially loaded beyond plasticity.

Definition

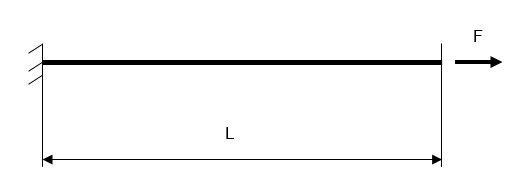

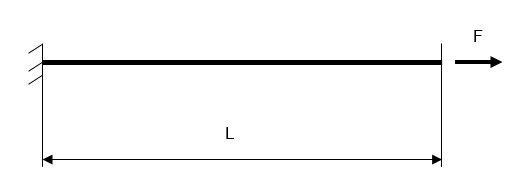

Figure 1.

Bar dimensions are 10 x 10 x 200 mm. Strain-stress curve of the bar material is

defined by the power law:

(1)

Where,

-

- Strength coefficient.

-

- Must be in the range [0,1].

-

=0

- Material is perfectly plastic.

-

=1

- Material is elastic.

The left end of the bar is clamped and the right end is loaded with force F.

The material properties are:

- Properties

- Value

-

- 530 MPa

-

- 0.26

- Poisson's Ratio

- 0

Figure 2. Corresponded strain-stress curve

Note: Elasticity modulus defined by the first two points of the strain-stress

curve is E=2.67324e+10 Pa.

The study was performed for the following load F values: 20000 N, 25000 N, and 30000

N

Reference Solution

One-dimensional analytical reference solution is described here.

At strain

and stress

, the residual strain is:

(2)

Where,

-

- Total strain in the bar.

-

- Elastic component of the total strain.

-

- Residual strain.

-

- Bar cross-section area.

Then residual displacement at the right end of the bar.

(3)

Results

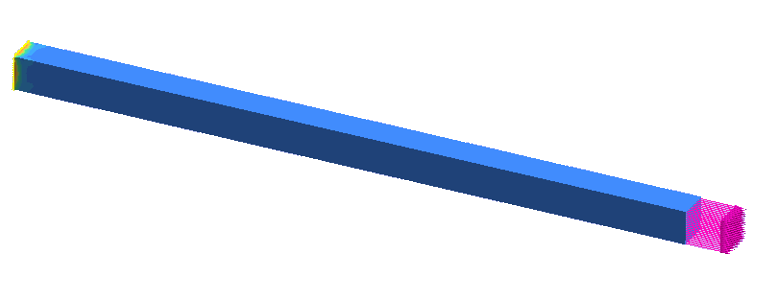

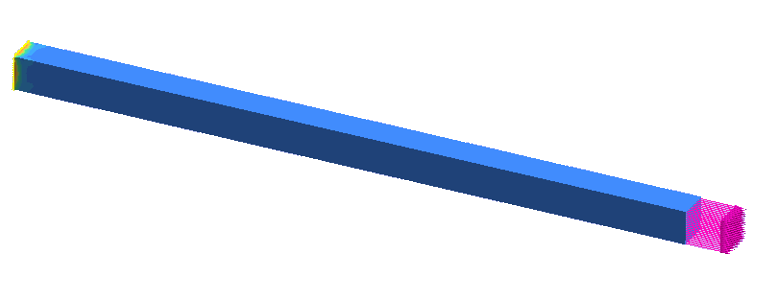

The bar was modeled as a 3D solid. The left end of the solid was fixed and the right

end loaded with axial force (

Figure 3).

Figure 3.

The following table summarizes the residual deformations results.

| Force F [N] |

SOL Reference, Residual

Displacement [mm] |

SimSolid, Residual Displacement

[mm] |

% Difference |

| 20000 |

3.22 |

3.43 |

6.78% |

| 25000 |

9.16 |

9.172 |

0.13% |

| 30000 |

19.077 |

19.14 |

0.33% |

Figure 4. von Mises stress distribution at load F=30000

N